The NGO company offers the following types of compressor equipment for delivery:

- Booster compressor stations of fuel gas for gas turbines

- Booster compressor stations and installations for the preparation of APG and NG

- Process compressors for various industries

- Air compressor stations

Our equipment has the following advantages:

- custom—made and required parameters, taking into account the peculiarities of operation and the composition of the source gas

- high reliability coefficient – 99%

- quality control system ISO 9001

- work in any climatic conditions, including extreme

- preparation of any types of gas

- automation of control with data transmission to the top-level ASU TP

- automation of group regulation of compressor units

- the ability to function at extremely low gas pressure at the inlet

- compact design in several versions

- the maximum level of factory readiness for delivery

Booster compressor stations

Booster compressor stations (DKS) and installations (DKU) operate in the electric power industry, oil and gas industry, petrochemistry and other industries. They have one thing in common: DKU is the most important technological link in gas preparation.

Each DKU application project is created based on the customer’s requirements and implemented individually. The development of an engineering solution and equipment configuration are carried out taking into account the type and composition of the source gas, operating conditions, parameters of the associated equipment, and the scope of application.

The scope of application of compressor units and booster compressor stations is determined by the following directions:- preparation of fuel gas for turbines of combined-cycle gas plants and gas turbine power plants of various capacities;

- preparation of associated (PNG) and low-pressure (NNG) petroleum gas in various ways of its use.

General functionality

The proposed booster compressor units are capable of compressing hydrocarbon gas to a pressure of 75 bar for subsequent use at electric power and oil and gas industry facilities.

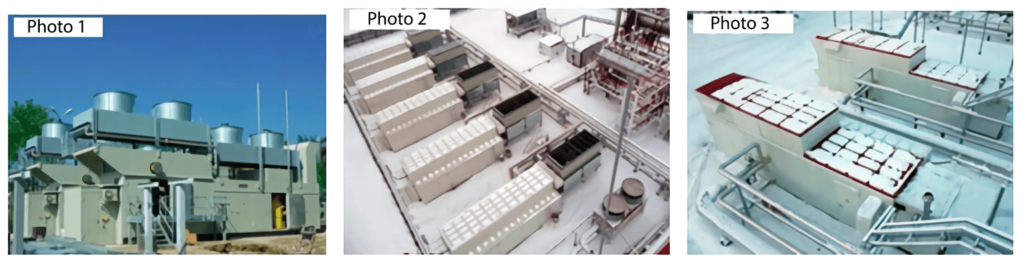

If it is necessary to ensure a high degree of pressure increase, modern two-stage compressor units are used (photo 1). They allow gas to be compressed in two stages — without intermediate cooling. This technology ensures stable operation of gas compressors over the entire range of suction pressure changes, regardless of the supply line.

In the electric power industry, the technological capabilities of various modifications of DKU allow one installation to supply fuel gas to turbines with a capacity from 1 to 200 MW. The proposed gas booster equipment has the ability to pump natural or associated petroleum gas with a volume of 200 to 50,000 m3/h using one compressor unit or several DKU combined into a booster compressor station (photo 2). This is achieved by automating group regulation.

Booster compressor units designed specifically for low–pressure petroleum gas (photo 3) are capable of preparing associated gas even at extremely low inlet pressure values – from 0.7 bar (abs).

These DKU are reliably operated when working with heavy petroleum gases with a density of up to 3.0 kg/m3; aggressive gases with a high content of hydrosulfides (H2S); in extreme climatic conditions.

| Application | Turbine power (MW) | Capacity (m3/h) | Minimum inlet pressure (bar, abs) | Maximum pressure on output (bar) |

| Electric power industry | 1 … 200 | 200 … 50 000 | 2 | 75 |

| Oil and gas | – | 200 … 50 000 | 0,7 | 75 |

- custom-made and required parameters, taking into account the features of operation and composition of the ex. gas

- high reliability factor 99%

- ISO 9001 quality control system

- ability to work in any climatic conditions

- operational experience with various gas turbines from leading manufacturers

- preparation of various types of gas — natural, associated petroleum, biogas, etc.

- automation of control with data transfer to the top-level ASU TP

- automation of group regulation of several DKU as part of a booster compressor station

- the ability to provide a high degree of pressure increase and function at extremely low inlet pressure

- compact design in several versions (photo below)

- the maximum level of factory readiness for delivery

DKU used in the oil and gas complex for the preparation of PNG have additional advantages:

- experience working with heavy oil gases with a density of up to 3.0 kg/m3

- operation with aggressive gases with a high content of hydrosulfides (H2S)

- gas preparation at extremely low inlet pressure, about 0.7 bar abs.

- reliable operation in severe and extreme climatic conditions

- redundancy of some systems and compressor units

- the use of special alloys and anti-corrosion materials in the manufacture of individual elements of the DKU

Air compressor stations

Air compressor stations are designed for use in the energy, oil and gas, engineering, construction and other industries. VKS provides compressed, dry and clean air for pneumatic equipment for various purposes: pneumatic valves, valves and regulators, pneumatic tools, welding posts, etc.

VKS is delivered in a block-modular design. The VKS all-weather shelter is equipped with safety and life support systems and minimizes the dependence of equipment on operating conditions. The air compressor stations offered by our company have a high degree of factory readiness. This allows specialists to carry out installation and commissioning work in the shortest possible time.

The automated control system VKS performs the following functions:- automatic activation of the backup compressor unit

- remote switching of operating and backup compressors

- automatic maintenance of the set pressure in the compressor switching network depending on the hourly operating time and according to the set time interval

Air compressor stations are supplied to the maximum degree of factory readiness.

| Specifications | Units of measurement | Meaning |

| Compressible gas | – | air |

| Dehumidified air performance | nm3/min | 1,2…8,5 |

| Working pressure | atm. (isb) | 7,5 |

| Intake air temperature | °C | -40…+40 |

| The air temperature at the injection, no more | °C | +50 |

| Oil content in compressed air, no more | ppm | 0,003 |

| The size of solid particles at the outlet, no more | microns | 0,01 |

| The installed capacity of the station is up to | kW | 200 |